The Zinc die casting line at Kemlows and the experience of the team goes back to the very start of the company.

Since those early days the technology has been upgraded as new equipment replaced old.

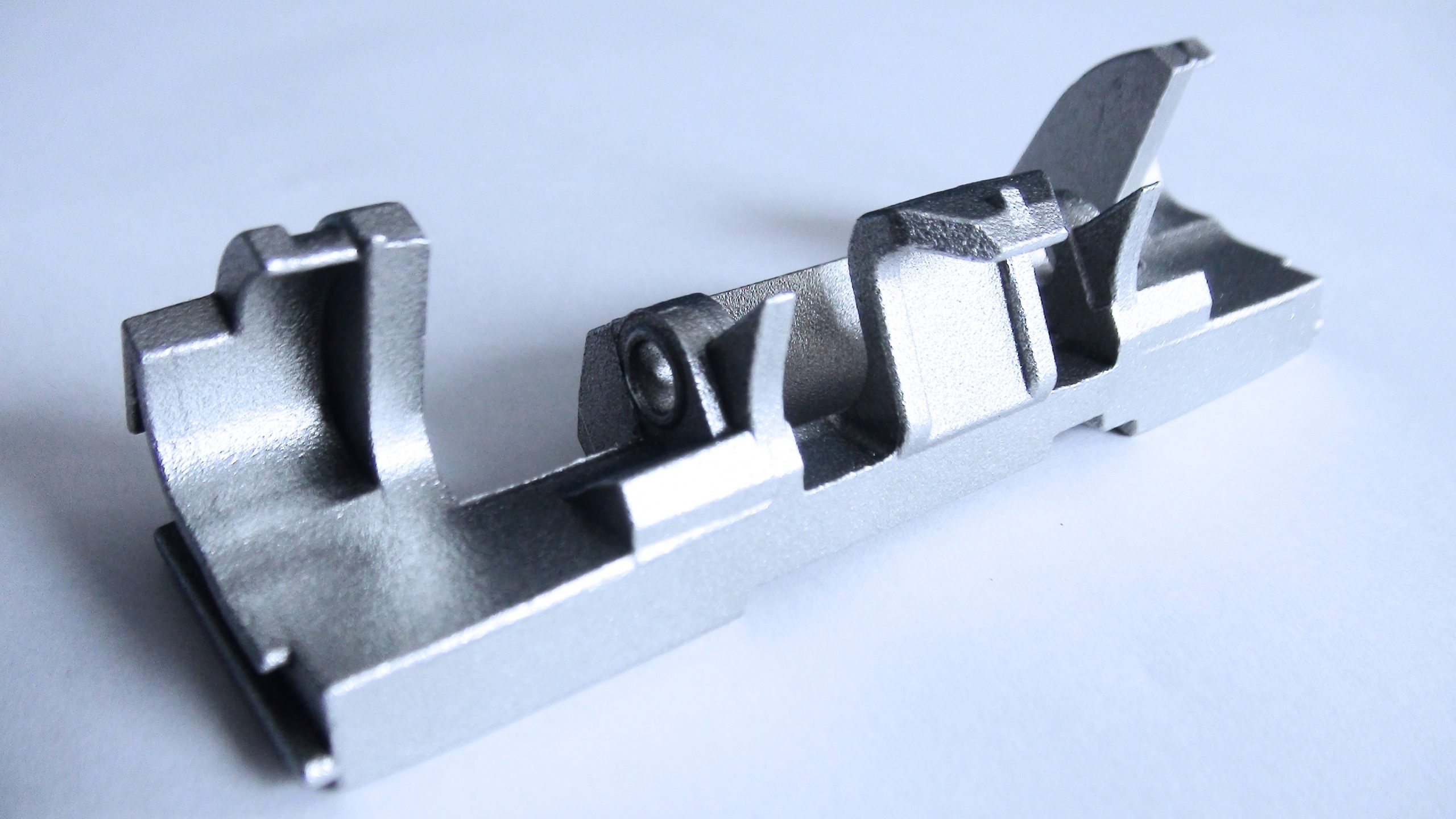

High specification hot chamber machines are employed to produce consistent quality zinc die castings time after time.

The latest specification hot chamber machines are employed to produce consistent quality castings time after time.

The casting capability across the zinc machines allows zinc casting production up to 4 kg.

The special properties of zinc based alloys, their castability and low melting point, allows very close tolerances to be cast, eliminating machining to all but the tightest controlled dimensions, such as bearing bores.

The finishes that can be applied to zinc based castings is legendary, from raw polished to gold plating and every option in between.

The lower cost of tooling associated with zinc casting alloys and the extended die life makes this alloy choice ideal for certain options. Half a million shots are regularly achieved before tooling requires refurbishment or replacement. This, together with its finish plating options, close tolerances achievable, plus its intrinsic weight, ensures there will be a steady future for this alloy and casting system.

Zinc Die casting Machines

Frech 125t – 2 off automatic die casting cells

Frech 80t – 1 off automatic diec asting cell

Frech 50t – 1 off automatic die casting cell