Quality is at the centre of our Business goal, which is to consistently accomplish the highest of standards every time.

To show our commitment to quality we have successfully attained important accreditations.

We are currently accredited to BS EN ISO 9001:2015 and IATF 16949:2016. These standards form the basis of the management’s philosophy, around which the Kemlows team conducts quality planning and control.

Quality doesn’t end with these accreditations, it begins. Kemlows’ commitment to excellence means applying the highest quality standards possible at all times and to all aspects of our business.

In production, this means having tried and tested, continually improving quality systems, at every stage of the manufacturing procedure; from design concept right through to the finished goods being delivered to the customer.

At Kemlows, quality means making sure the customer service you receive is the same high standard throughout the whole trading relationship.

When you choose Kemlows, you get mutual trust, respect, and commitment to customer satisfaction.

Quality is ingrained into every one of our services.

New products are fully analysed by the team at Kemlows where systems are utilised to eliminate potential production difficulties. This smoothes the development from design concept through to trouble free production. Our diecasting experience enables an early awareness of any “problem” design features. Consequently, following communication with our customer, we eliminate them from the process. Split lines, draw taper, tolerance control, etc. are all carefully thought through. This will minimise the risk of difficulties during manufacturing, ensuring consistent on time delivery, thanks to consistent trouble free production.

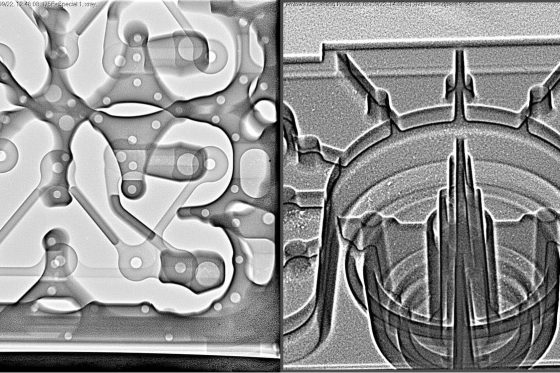

A ‘real time’ x-ray cabinet affords the opportunity to ensure quality castings during each and every run.

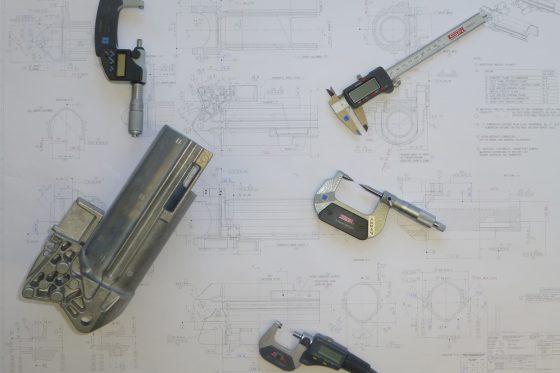

In addition, up to date measuring equipment includes programmable co-ordinate measuring machines (CMM’s), where components can be measured and dimensions statistically logged for analysis and subsequent quality improvement action.

Support for our customer’s product improvement doesn’t stop at the design stage, it continues throughout manufacture with continuous improvement a reality, not a slogan.

From incoming materials to finished goods delivered to the customer, Kemlows plans, implements, reviews and measures, to ensure our reputation of reliable first class product, supported by first class service, is delivered and maintained.

Key Quality Equipment